Adsorption Type Heatless Compressed Air Dryers

Drowning Efficiency: Problems Caused by Water in Compressed Air

The importance of air dryers in a compressed air system cannot be overstated, as many industrial tools and processes rely on moisture-free compressed air to function efficiently.

- During the compression cycle, free water is often generated, leading to corrosion and rust formation within the system. These rust particles can circulate through the compressed air network, causing equipment damage and contamination of end products.

- Excess moisture can foster bacteria growth or be absorbed by processed materials, leading to compromised quality and potential product spoilage.

- Water in compressed air can result in rust deposits, equipment malfunctions, solidification of media, and defects in coatings, such as bubbling or the "orange peel effect." These issues contribute to inefficiencies, material waste, and costly downtime.

To mitigate these issues and ensure an effective pneumatic system, utilizing air dryers to produce clean, dry compressed air is essential, reducing unnecessary costs and safeguarding the system against damages.

The Two Ways to Remove Moisture:

Refrigeration Type Air Dryers

Cooling is one of the most effective methods for removing moisture from compressed air. Our Refrigerated Air Dryers use a closed-loop refrigerant circuit to cool the compressed air to a controlled temperature, causing moisture to condense and separate. To prevent freezing, the air/gas is cooled to a minimum temperature of around +2-3°C at 7Kgf/cm² operating pressure, ensuring optimal performance. These dryers are ideal for applications where atmospheric dew points of -20 to -22°C are acceptable.

Refrigerant dryers incorporate both an air-to-air heat exchanger and an air-to-refrigerant heat exchanger. In the first stage, incoming air is pre-cooled by outgoing air. In the second stage, compressed air is further cooled to approximately 3°C within the Freon circuit, leading to moisture condensation. As a result, the relative humidity drops below 50% in the subsequent heating phase. This process prevents free water and corrosion, providing efficient and reliable moisture control. Our refrigerant dryers are available in water-cooled and air-cooled variants to suit different industrial needs.

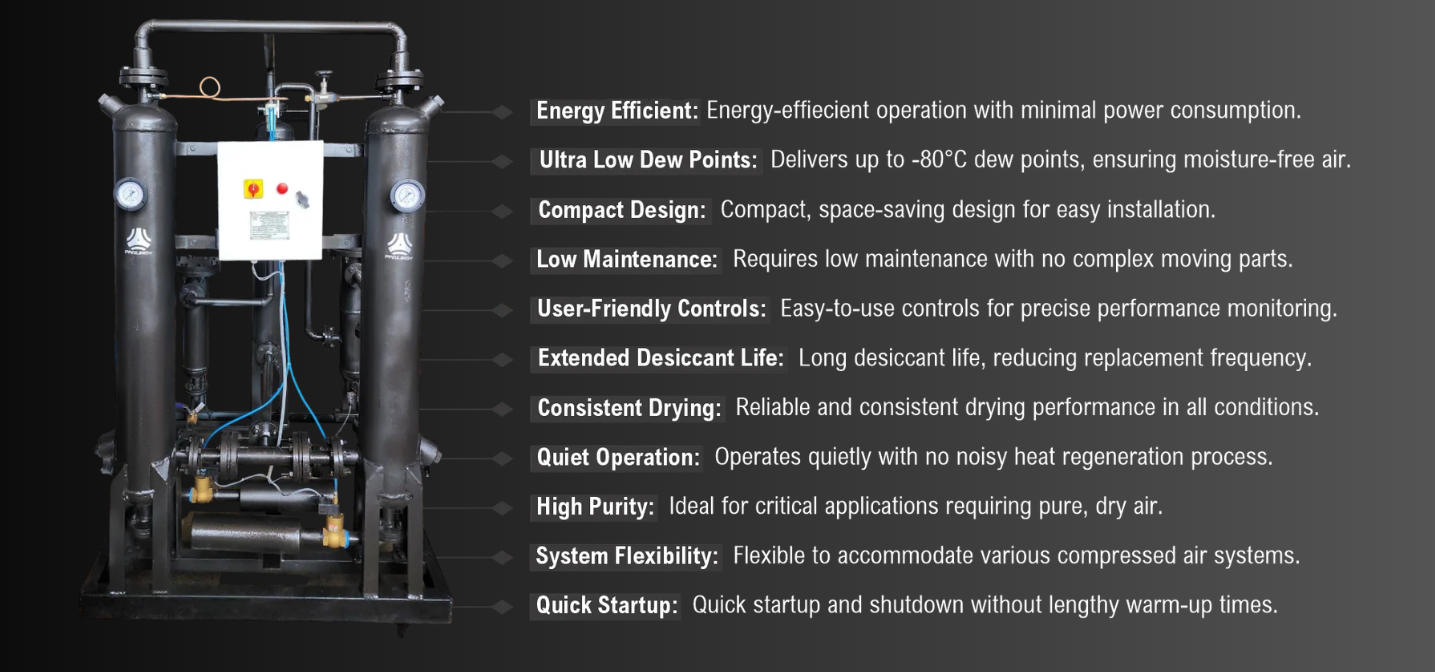

Heatless Adsorption Type Dryers

Desiccant air dryers, particularly the Heatless Type, are ideal for compressed air applications that require a pressure dew point below 0°C. These dryers utilize natural desiccant adsorption to efficiently remove moisture from the compressed air stream.

The Heatless Type Dryer consists of two adjacent pressure vessels filled with hygroscopic desiccant beads. The system automatically cycles wet air between these two towers, with one actively absorbing moisture while the other undergoes regeneration.

During operation, wet air enters one tower, where the desiccant bed absorbs moisture to deliver dry compressed air. Meanwhile, a small portion of this dried air is redirected to the second tower for desiccant regeneration, before being purged to the atmosphere. This cold regeneration process consumes around 8-10% of the compressed air, making it relatively more costly. However, these dryers ensure a continuous supply of ultra-dry air, achieving dew points as low as -70°C to -80°C at atmospheric pressure, making them highly effective for critical applications requiring superior moisture control

Other Types of Adsorption Dryers Offered are

- Embedded Internal Heat Regenerated Adsorption Dryers: These dryers utilize internal heating elements for efficient desiccant regeneration.

- Blower Heat Regenerated Zero-Loss Adsorption Dryers: These systems use an external blower and heater for regeneration, eliminating purge air loss and improving efficiency.

- Split Flow Zero-Loss Adsorption Dryers: These dryers recycle a portion of the dried air for regeneration, significantly reducing energy consumption.

- Heat of Compression Zero-Loss Adsorption Dryers: These innovative dryers utilize the inherent heat generated during the compression process for regeneration, ensuring zero air loss.

Features & Benefits

- Brazed Plate Heat Exchanger Technology ensures higher efficiency compared to traditional coil heat exchangers.

- 3-in-1 Heat Exchanger Technology enables efficient pre-cooling, Freon cooling, and moisture separation within a compact design.

- Fully automatic push-button start for effortless operation.

- No dedicated operators are required, reducing labour costs and simplifying use.

- Tailored customization to meet specific air drying requirements.

- Seamless integration into unique compressed air setups for optimal performance.

- Comprehensive solution for all air drying needs.

- Wide range of dew points available for different applications.

- Achievable dew points from -20°C to -80°C for precise moisture control.

- High-quality components ensure durability and reliability.

- Modular skid-mounted design for easy maintenance access.

- Minimized downtimes with quick and efficient servicing.

- Gradual depressurization & re-pressurization to prevent bed attrition.

- Interior epoxy coating on towers for enhanced protection.

- Meets or exceeds industry regulations for compliance and safety, ensuring reliable operation in compressed air systems.

- Fabricated as per ASME Sec. VIII, Div-1 or IS 2825 codes for quality assurance.

- Panurgy offers expert technical support on thousands of applications.

- We can help you choose the right Dryer for your application.

Dew Point Selection:

The dew point measures the moisture content in the air, indicating the temperature at which condensation begins. A lower dew point signifies drier air. For instance, air with a -40°C dew point ensures no moisture condenses unless the temperature drops below -40°C. However, achieving a lower dew point increases the operational cost of an air dryer. Therefore, selecting the appropriate dew point is crucial for maintaining cost-effective and efficient system performance.

Applications

| Application | ISO Class | Dew Pt. | Max Value in (MG/M³) | Dryer Type | |||

|---|---|---|---|---|---|---|---|

| Dust | Oil | R | H | HL | |||

| Agitation | 5 | +7 | NS | 25 | |||

| Storage Air | 2 | -40 | 0.5 | 0.1 | |||

| Measuring Air | 3 | -20 | 1 | 1.0 | |||

| Air Turbines | 2 | -40 | 0.5 | 0.1 | |||

| Stones & Glass | 3 | -20 | 1 | 1.0 | |||

| Shoes/Leather | 3 | -20 | 1 | 1.0 | |||

| Clean Mach. Parts | 4 | +3 | NS | 5 | |||

| Granular Subs. Conv. | 3 | -20 | 1 | 1.0 | |||

| Foundry Machines | 4 | +3 | NS | 5 | |||

| FOOD & BEVERAGES | 3 | -20 | 1 | 1.0 | |||

| MACHINE TOOLS | 3 | -20 | 1 | 1.0 | |||

| PACK-TEXTILE MACH. | 3 | -20 | 1 | 1.0 | |||

| PHOTOGRAPHIC FILM | 1 | -70 | 0.1 | 0.01 | |||

| PNEUMATIC CYLINDER | 3 | -20 | 1 | 1.0 | |||

| PRESSURE CONTROLLER | 2 | -40 | 0.5 | 0.1 | |||

| PROCESS CONTROL | 2 | -40 | 0.5 | 0.1 | |||

| SPRAY PAINTING | 2 | -40 | 0.5 | 0.1 | |||

| POWDER COATING | 2 | -40 | 0.5 | 0.1 | |||

| WELDING MACHINES | 4 | +3 | NS | 5 | |||

| SULPHUR BURNING | 1 | -70 | 0.1 | 0.01 | |||

| ELECTRONIC APPLICATION | 2 | -40 | 0.5 | 0.1 | |||

| RICE SORTING MACH. | 4 | +3 | NS | 5 | |||

| CEMENT AERATION | 3 | -20 | 1 | 1.0 | |||

R: refrigerated type, H: heated type, HL: heatless type air dryer, NS: Not Specified.

Quality classes for compressed air according to ISO/DIN 8573/1. Above selection chart is only indicative. For final selection, capacity and ambient conditions are important. For detailed selection, consult Panurgy application engineers.

Our Recommendations

Details Required for Preparing Proposals

The following details are required for preparing proposals:

- Air/Gas Flow Rate, Pressure, and Temperature, along with the Compressor Make & Model.

- Required Dew Point and its Application.

- Compressor Type – Lubricated or Non-Lubricated.

- Intended Use of Compressed Air/Gas.