Compressed Air Turnkey Piping

Overview

At Integrated Engineers & Contractors, we recognize the importance of a well-constructed compressed air piping system in ensuring operational efficiency and lowering energy costs. That’s why we offer comprehensive, tailored services designed to meet the specific needs of each customer. Our team of experienced professionals excels in designing and installing efficient compressed air piping systems that provide optimal air delivery to all points of usage.

We also offer extensive compressed air audits to assess the performance and efficiency of existing systems. Our skilled technicians perform detailed evaluations to pinpoint areas that can be improved, providing tailored recommendations to enhance system performance, cut energy consumption, and reduce maintenance needs. By focusing on quality and customer satisfaction, we aim to provide cost-effective solutions that maximize both the value and lifespan of your compressed air infrastructure. Partner with us to optimize your compressed air system and realize its full potential for your operations.

The primary role of the compressed air piping system is to deliver compressed air to the points where it is needed. This air must be delivered in sufficient volume, with the correct quality and pressure, to effectively power all components relying on compressed air. Given the high cost of producing compressed air, a poorly designed system can significantly increase energy expenses, lead to equipment failures, decrease production efficiency, and require frequent maintenance. In most cases, improving the compressed air piping system will quickly pay off, providing long-term savings and operational benefits.

Compressor Discharge Piping

Discharge piping from a compressor without an integral aftercooler can experience extremely high temperatures. It is essential to use pipes capable of withstanding these elevated temperatures. Additionally, the heat can lead to thermal expansion, which can place extra stress on the piping system. It is important to consult the compressor manufacturer's guidelines when selecting and installing discharge piping.

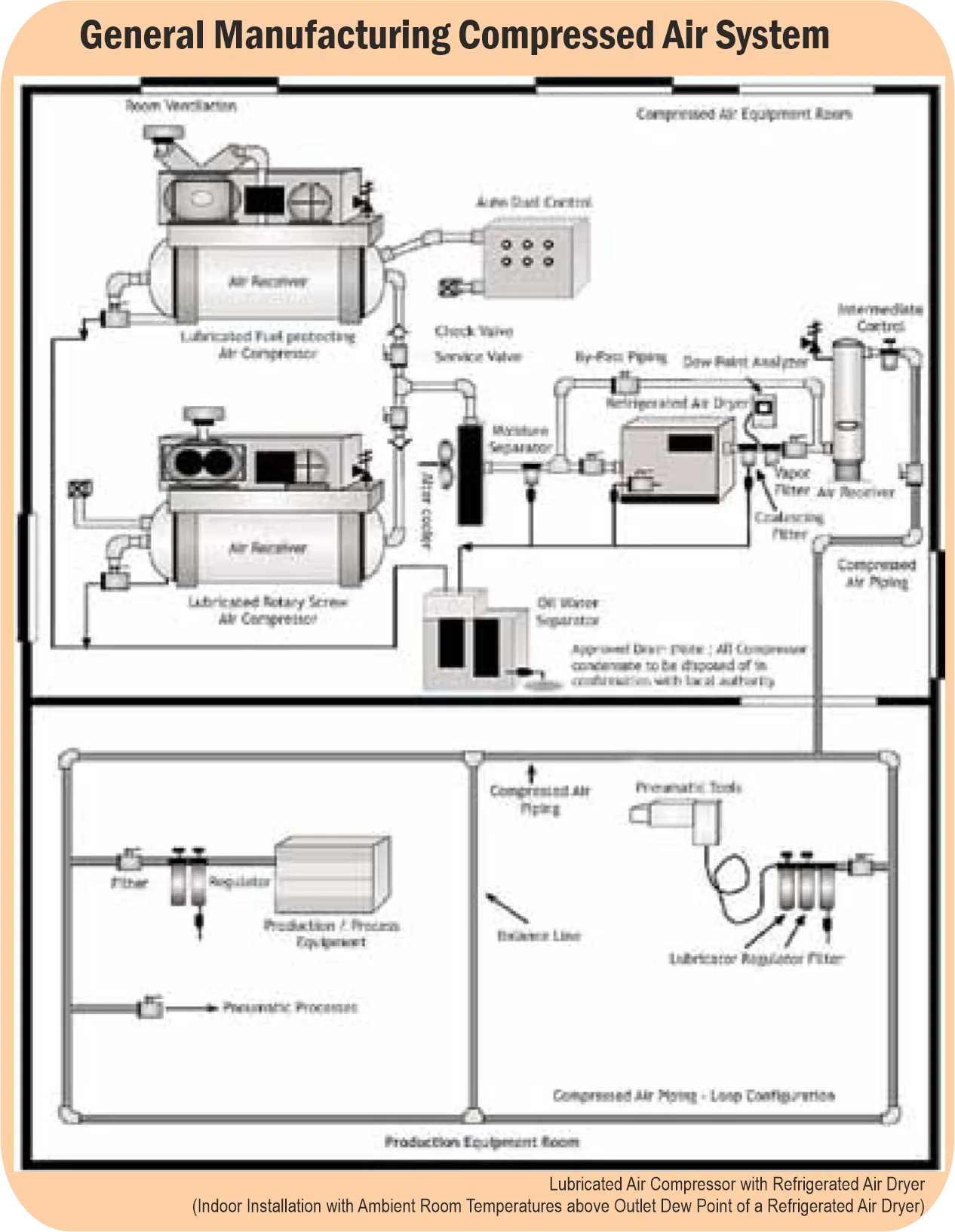

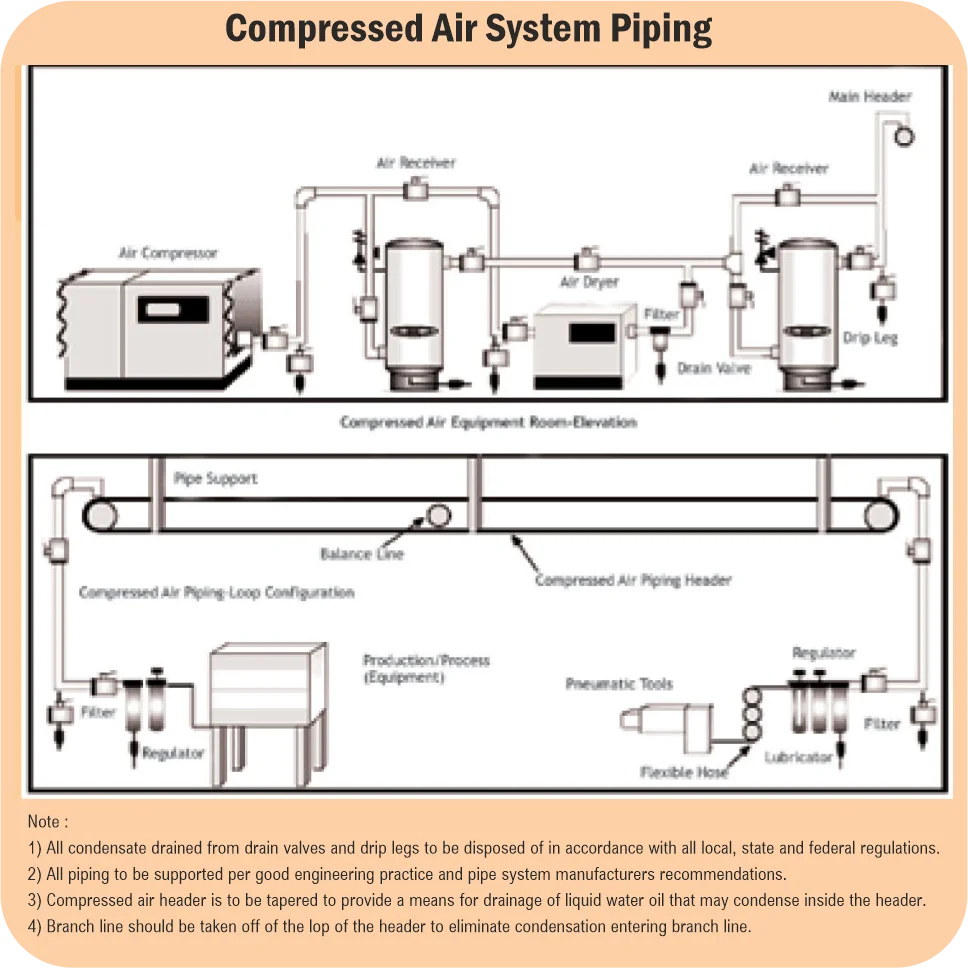

Condensate Control

Condensate control is a critical consideration when designing and installing a compressed air piping system. To effectively manage condensate, drip legs should be installed at all low points in the system. A drip leg is an extension of a pipe that collects condensate, and it should be followed by a drain trap. Ideally, an automatic drain should be used for this purpose (refer to the drain valves section for further information on available options).

To remove oil, condensate, or cooling water (in case of water-cooled aftercooler leakage), install a low-point drain in the discharge pipe before the aftercooler. Ensure proper connection between the aftercooler outlet and the separator inlet. Improper connections can lead to either ineffective aftercooling or poor moisture separation.

The main header pipe in the system should be sloped downward in the direction of compressed air flow. A general guideline is to slope 1” per 10 feet of pipe. This slope directs the condensation toward low points in the system for easy collection and removal.

Additionally, ensure that the piping after the aftercooler slopes downward into the bottom connection of the air receiver, aiding condensate drainage. In case the water-cooled aftercooler experiences an internal water leak, the slope will direct water toward the receiver rather than the compressor. Another effective method for managing condensation is to take all branch connections from the top of the airline. This helps prevent condensation from entering the branch connections while allowing it to continue flowing to the system’s low points.

Pressure Drop

Pressure drop in a compressed air system is a critical factor. Pressure drop is caused by friction of the compressed air flowing against the inside of the pipe and through valves, tees, elbows, and other components that make up a complete compressed air piping system. Pressure drop can be affected by pipe size, the type of pipes used, and the number and type of valves, couplings, and bends in the system. Each header or main should be furnished with outlets as close as possible to the point of application. This avoids significant pressure drops through the hose and allows shorter hose lengths to be used. To avoid carryover of condensed moisture to tools, outlets should be taken from the top of the pipeline. Larger pipe sizes, shorter pipe and hose lengths, smooth wall pipe, long radius swept tees, and long radius elbows all help reduce pressure drop within a compressed air piping system. In recent years, we have developed piping systems especially for compressed air. These compressed air piping systems typically have smooth walls, are lightweight, and reduce the installation costs associated with copper and stainless steel piping systems.

Loop Pipe System

The layout of the system can also affect the compressed air system. A very efficient compressed air piping system design is a loop design. The loop design allows airflow in two directions to a point of use. This can cut the overall pipe length to a point in half, reducing pressure drop. It also means that a large volume user of compressed air in a system may not starve users downstream since they can draw air from another direction. In many cases, a balanced line is also recommended, providing another source of air. Reducing the velocity of the airflow through the compressed air piping system is another benefit of the loop design. In cases where there is a large volume of users, an auxiliary receiver can be installed. This reduces the velocity, which in turn reduces the friction against the pipe walls and reduces pressure drop. Receivers should be positioned close to the far ends or at points of infrequent heavy use of long distribution lines. Many peak demands for air are short-lived, and storage capacity near these points helps avoid excessive pressure drop and may allow a smaller compressor to be used.