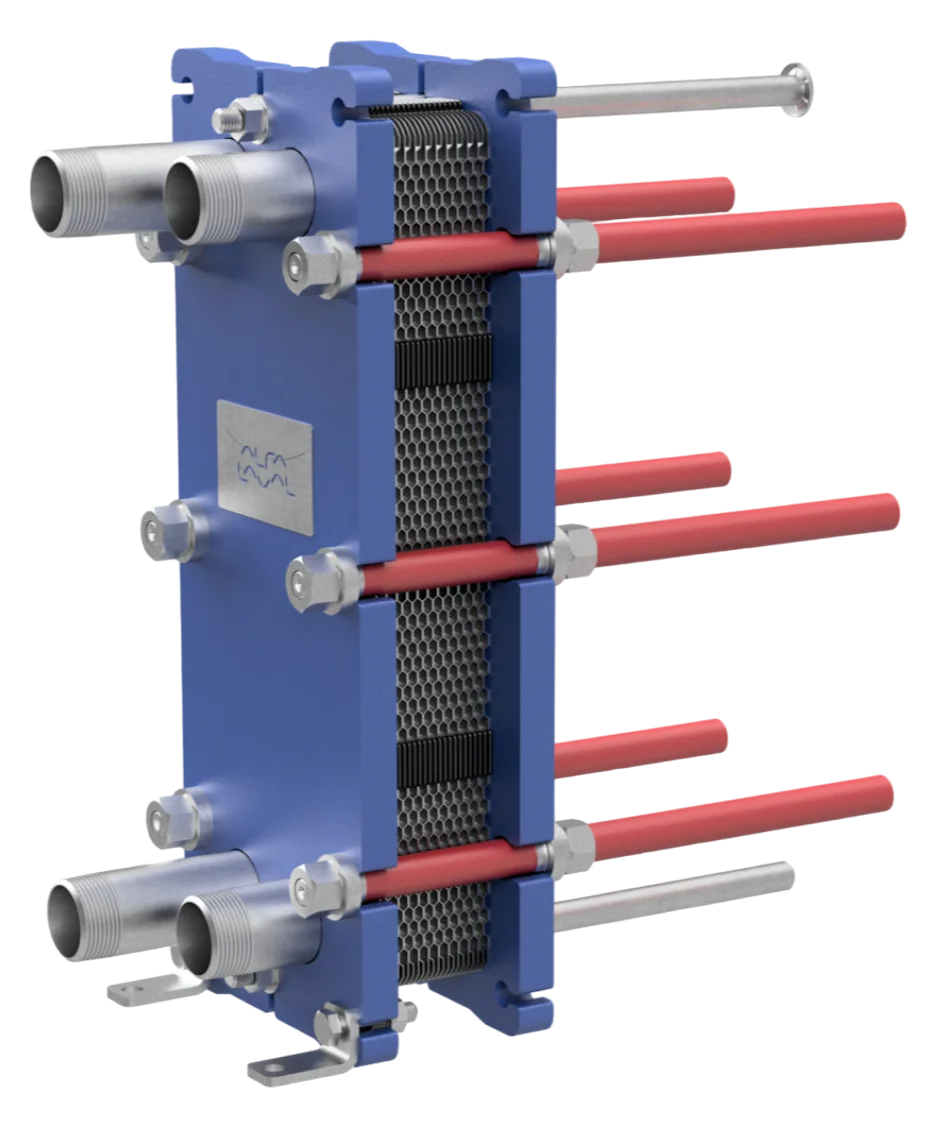

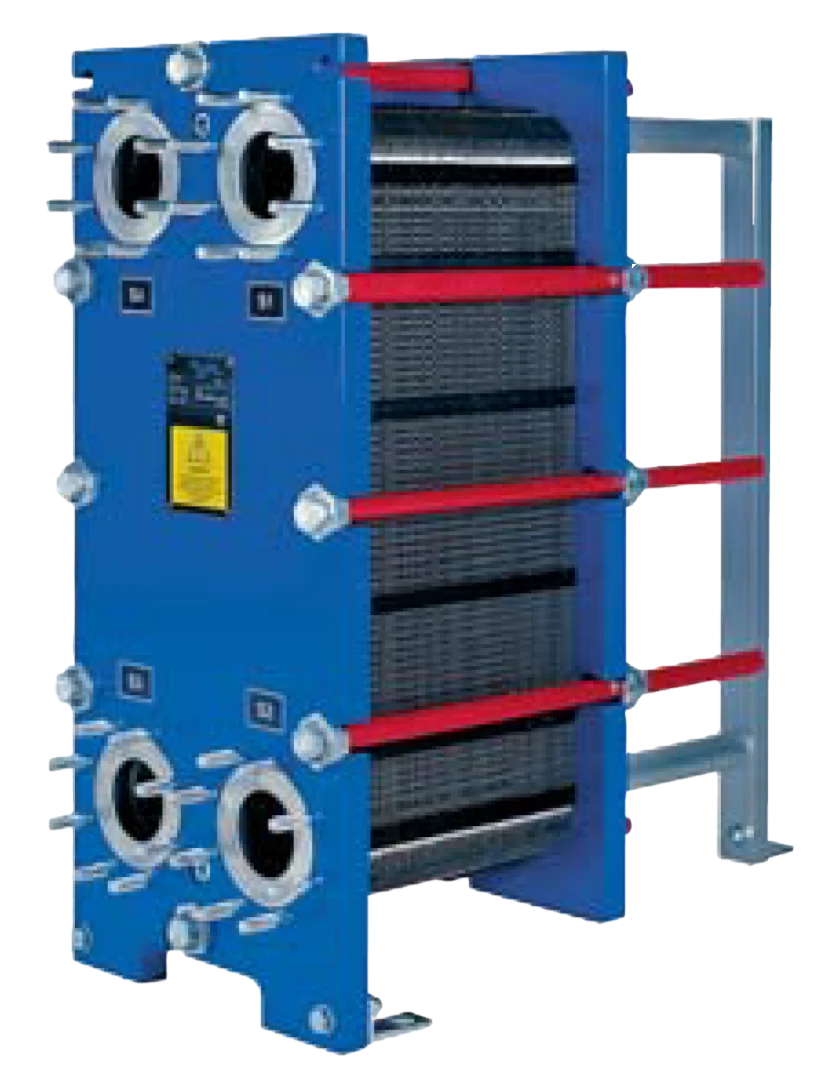

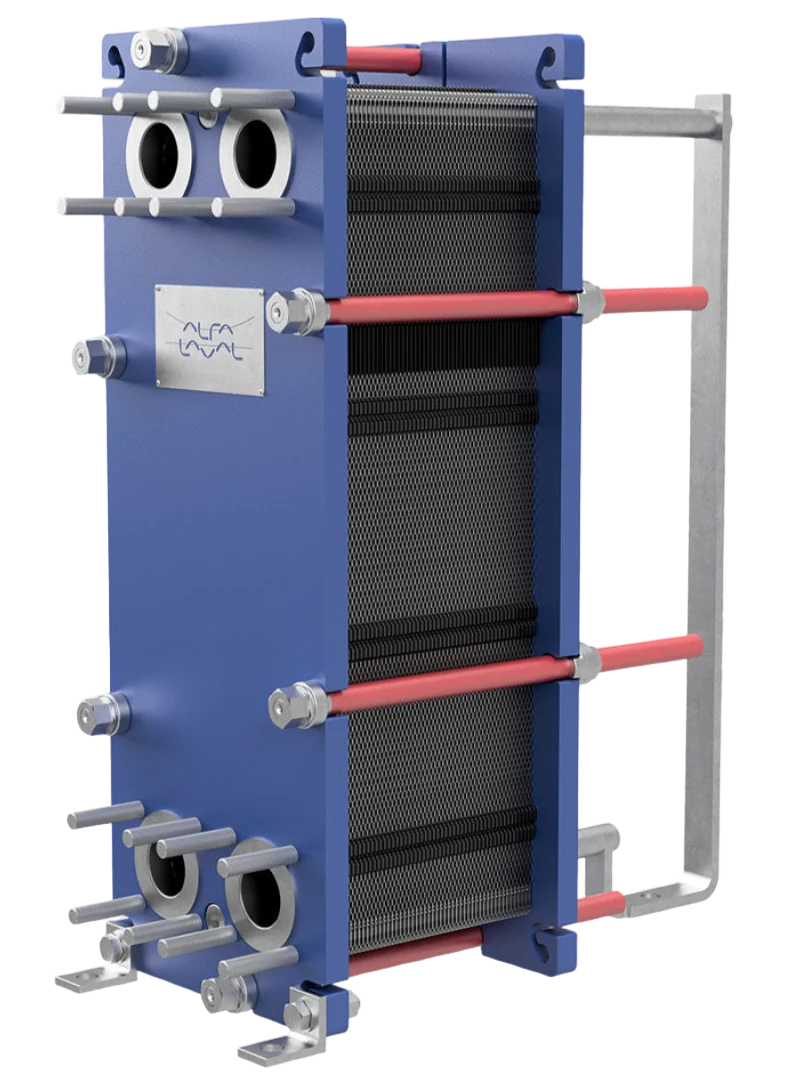

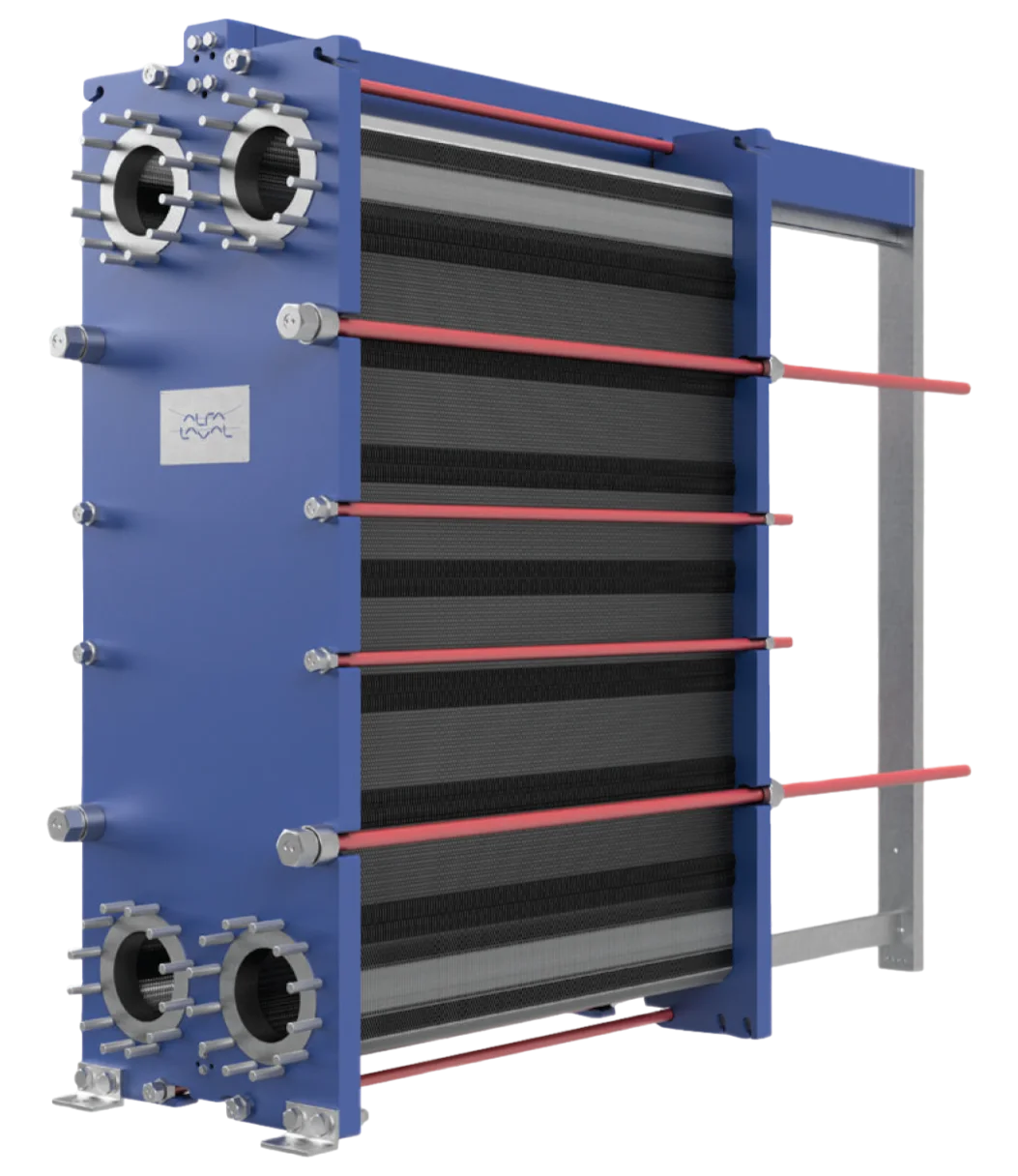

Gasketed Plate Heat Exchangers

Overview

Gasketed Plate Heat Exchangers (GPHE) are highly efficient and versatile solutions for industrial heat transfer applications. These exchangers feature a series of corrugated plates, held together by durable gaskets, creating separate fluid channels for optimal heat exchange. GPHEs are widely preferred for their high thermal efficiency, easy maintenance, and scalability, making them ideal for process cooling, industrial heating, and energy recovery. Their modular design allows for easy expansion or modifications, ensuring cost-effective performance in HVAC systems, chemical processing, food & beverage industries, and power plants.

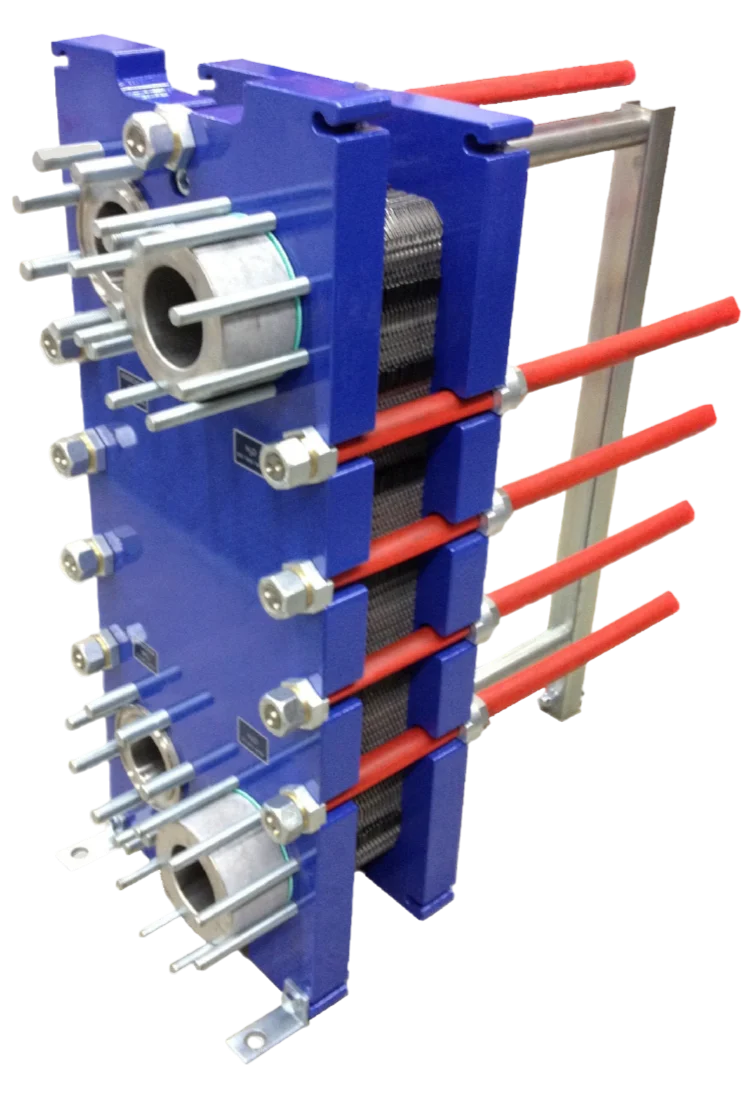

Semi-welded Plate Heat Exchangers (SWPHE) offer a robust combination of welded and gasket designs, providing enhanced durability and leak-proof operation. These exchangers are specifically designed to handle aggressive, high-pressure, or hazardous fluids, such as ammonia, hydrocarbons, and industrial chemicals. With their high thermal efficiency and superior corrosion resistance, SWPHEs are widely used in refrigeration systems, petrochemical industries, and power generation plants where safety, reliability, and optimal heat transfer are essential.

Alfa Laval Gasketed Plate Heat Exchangers

At Integrated Engineers & Contractors, we take pride in offering one of the largest inventories of Alfa Laval Gasketed Plate Heat Exchangers (GPHEs) and Semi-Welded Plate Heat Exchangers (SWPHEs). Our extensive product range is designed to meet diverse industrial heat transfer needs, ensuring maximum efficiency, durability, and performance.

Gasketed Plate Heat Exchangers

Applications

Shell & Tube Replacement

Upgrading from traditional shell and tube heat exchangers to gasketed plate heat exchangers (GPHEs) significantly enhances thermal efficiency, minimizes maintenance requirements, and optimizes space utilization. These heat exchangers are ideal for industrial applications where a compact, high-performance solution is needed for process heating and cooling.

Process Cooling

GPHEs work seamlessly with chillers for indirect cooling applications, making them perfect for oil cooling, milk cooling, acid cooling, and other critical industrial processes. They provide consistent temperature control, preventing thermal stress on equipment, ensuring smooth operations, and improving overall system efficiency.

Cooling Tower Interchanger

As intermediaries in cooling tower systems, GPHEs improve heat exchange efficiency between cooling tower water and process fluids, effectively reducing scaling and corrosion. This results in longer equipment lifespan, lower maintenance costs, and better energy efficiency in HVAC, power plants, and industrial cooling systems.

Applications

Process Heating

Gasketed Plate Heat Exchangers (GPHEs) provide efficient and precise heating for a wide range of industrial applications. By transferring heat from steam or hot water to process fluids, they ensure uniform temperature control, enhance process consistency, and optimize energy efficiency. These heat exchangers are widely used in food processing, chemical industries, pharmaceutical manufacturing, and HVAC systems.

Gearbox Oil Cooling

GPHEs play a crucial role in cooling gearbox oil, preventing overheating, and maintaining optimal operational temperatures. This results in enhanced performance, increased reliability, and extended lifespan of gearboxes used in industrial machinery, heavy-duty equipment, and automotive applications.

Hydraulic Oil Cooling

Used extensively in hydraulic systems, GPHEs efficiently dissipate heat from hydraulic oil, preventing overheating and ensuring consistent machinery performance. By maintaining optimal temperature control, they help prolong the lifespan of hydraulic components, reduce downtime, and improve system efficiency in industries such as construction, mining, and manufacturing.

Applications

Quenching Oil Cooling

In metal processing and heat treatment industries, Gasketed Plate Heat Exchangers (GPHEs) play a vital role in cooling quenching oils to maintain optimal temperatures. This ensures proper hardening of metals, enhances material strength and improves product quality. By providing efficient and uniform cooling, GPHEs help in preventing oil degradation, reducing energy consumption, and extending the lifespan of industrial quenching systems.

Furnace Cooling

GPHEs are widely used in industrial furnaces to regulate temperatures and prevent overheating in high-temperature applications such as steel manufacturing, glass production, and metal casting. These heat exchangers efficiently manage heat dissipation, ensuring safe and stable operation while reducing maintenance costs and improving energy efficiency.

Free Cooling with Chiller

GPHEs facilitate energy-efficient cooling solutions by enabling free cooling in colder months. Instead of relying on energy-intensive chillers, they use cooling tower water to achieve desired process temperatures, reducing energy consumption and operational costs. This method prevents scaling and thermal inefficiencies, making it a preferred choice for HVAC systems, data centres, and industrial cooling applications.

Applications

Heat Recovery from Air Compressors

Gasketed Plate Heat Exchangers (GPHEs) efficiently recover waste heat from air compressors, converting it into usable thermal energy for other industrial applications. By utilizing this otherwise lost heat, businesses can reduce energy consumption, lower operating costs, and enhance overall system efficiency. This method is commonly used in manufacturing plants, power generation, and HVAC systems to optimize thermal energy utilization.

Industrial Heat Recovery Solutions

GPHEs play a crucial role in heat recovery applications by capturing and repurposing excess heat from various fluid streams. This process helps preheat fluids in boilers, water heating systems, and industrial processes, significantly improving energy efficiency while minimizing fuel consumption and carbon emissions. Industries such as chemical processing, food and beverage, and pharmaceuticals benefit from this sustainable energy-saving technology.

Boiler Protection & Efficiency

GPHEs safeguard boiler systems by preventing contamination, scaling, and corrosion, ensuring consistent performance and long-term reliability. By isolating process fluids from the boiler, these heat exchangers enhance thermal efficiency, reduce maintenance requirements, and extend boiler lifespan. This makes them an essential component in industrial steam systems, district heating, and power plants where maintaining boiler integrity is critical.

Applications

Biotech and Pharmaceutical Industry

Gasketed Plate Heat Exchangers (GPHEs) play a vital role in the biotech and pharmaceutical sectors, ensuring precise temperature control in fermentation, purification, and formulation processes. They help maintain product integrity, support sterile conditions, and enhance process reliability. By optimizing thermal management, GPHEs contribute to higher efficiency in vaccine production, enzyme fermentation, and API manufacturing, making them indispensable for pharmaceutical and biotech facilities.

Chemical Processing

GPHEs are extensively used in chemical industries for efficient heat transfer, helping maintain stable reaction temperatures and ensuring optimal processing conditions. These heat exchangers can handle corrosive, hazardous, and high-viscosity fluids with maximum safety, making them essential for chemical synthesis, petrochemical refining, and speciality chemical production. Their compact design, high thermal efficiency, and ease of maintenance make them a preferred choice for energy-efficient chemical processing solutions.

Polyol and TDI Cooling in Polyurethane Production

GPHEs provide precise temperature control in polyol and TDI (Toluene Diisocyanate) cooling, which is essential for polyurethane foam manufacturing. Maintaining stable cooling conditions ensures consistent chemical reactions, resulting in uniform foam density, improved product quality, and enhanced production efficiency. These heat exchangers are widely used in the automotive, insulation, and furniture industries, where polyurethane foam applications are in high demand.

Applications

Energy and Utilities

Gasketed Plate Heat Exchangers (GPHEs) play a crucial role in the energy and utility sector, optimizing heat recovery, district heating, and cooling applications. They maximize energy efficiency, reduce fuel consumption, and help cut down operational costs. Industries such as power plants, renewable energy systems, and HVAC networks rely on GPHEs to improve thermal performance while ensuring sustainable energy management.

Food and Beverage Industry

GPHEs are widely used in the food and beverage sector for pasteurization, cooling, and heating processes. Their high heat transfer efficiency ensures precise temperature control, which is critical for food safety, extended shelf life, and compliance with stringent hygiene regulations. These heat exchangers are essential in dairy processing, brewing, beverage production, and confectionery manufacturing, contributing to consistent product quality and efficient energy utilization.

Water and Wastewater Treatment

In water and wastewater treatment facilities, GPHEs facilitate efficient heat recovery and temperature regulation, ensuring optimal process performance. They help industries reuse thermal energy, reducing overall energy consumption and environmental impact. Used in sewage treatment plants, desalination units, and industrial effluent systems, these heat exchangers contribute to cost-effective and eco-friendly water management solutions.

Applications

Chiller Condenser Protection

Gasketed Plate Heat Exchangers (GPHEs) play a vital role in chiller condenser protection by efficiently transferring heat from process fluids to cooling water. This prevents scaling, fouling, and mineral buildup in the condenser, ensuring optimal efficiency and extended lifespan of the chiller system. By maintaining clean and efficient heat transfer, GPHEs help in reducing maintenance costs and enhancing cooling performance in industrial and commercial HVAC applications.

HVAC and Refrigeration

GPHEs significantly enhance the efficiency of HVAC and refrigeration systems by ensuring effective heat exchange for both cooling and heating processes. They help reduce energy consumption, minimize thermal losses, and improve overall system performance. These heat exchangers are widely used in commercial buildings, data centres, supermarkets, and industrial refrigeration units, supporting energy-efficient climate control and sustainable cooling solutions.

Machinery and Manufacturing

In the machinery and manufacturing sectors, GPHEs are essential for cooling lubricants, hydraulic oils, and various industrial process fluids. By maintaining consistent operating temperatures, they improve machine efficiency, prevent overheating, and enhance equipment lifespan. Industries such as automotive, heavy machinery, metal processing, and chemical manufacturing rely on GPHEs for optimized thermal management and cost-effective production processes.

Features & Benefits of Gasketed Plate Heat Exchangers

- Compact & Space-Saving Design: Engineered with a lightweight and compact structure, GPHEs occupy minimum space while delivering high thermal efficiency. Their modular design makes them easy to integrate into HVAC, industrial cooling, and process heating systems, making them a preferred choice for space-constrained installations.

- Superior Energy Efficiency & Heat Transfer: With minimal temperature differences and optimized heat exchange, GPHEs help reduce energy consumption, improve chiller efficiency, and lower operational costs. These heat exchangers are designed for high-performance cooling and heating applications, ensuring maximum heat recovery in industrial processes and HVAC systems.

- Low Maintenance & Corrosion Resistance: Built to withstand harsh operating conditions, GPHEs feature low fouling properties, even when handling raw water, cooling brines, or corrosive fluids. Their corrosion-resistant materials ensure long-lasting durability, reducing maintenance frequency and enhancing system reliability.

- Easy Maintenance & Hassle-Free Servicing: The advanced bolt-closing system allows for quick disassembly, enabling easy cleaning, inspection, and plate replacement. The glue-free gasket design simplifies on-site replacement, minimizing downtime and making servicing cost-effective.

- Reliable & Leak-Proof Operation: Designed for high-pressure and high-temperature applications, GPHEs ensure zero risk of inter-linkage between fluids. Their fatigue-resistant construction provides long operational life, making them ideal for heavy-duty industrial and commercial applications.

- Optimized for Various Fluids & Refrigerants: GPHEs support multiple heat transfer applications, including cooling water, refrigerants, brines, and corrosive process fluids. Their adjustable heat transfer area allows for customized capacity adjustments, making them a versatile solution for HVAC, refrigeration, food processing, chemical, and pharmaceutical industries.

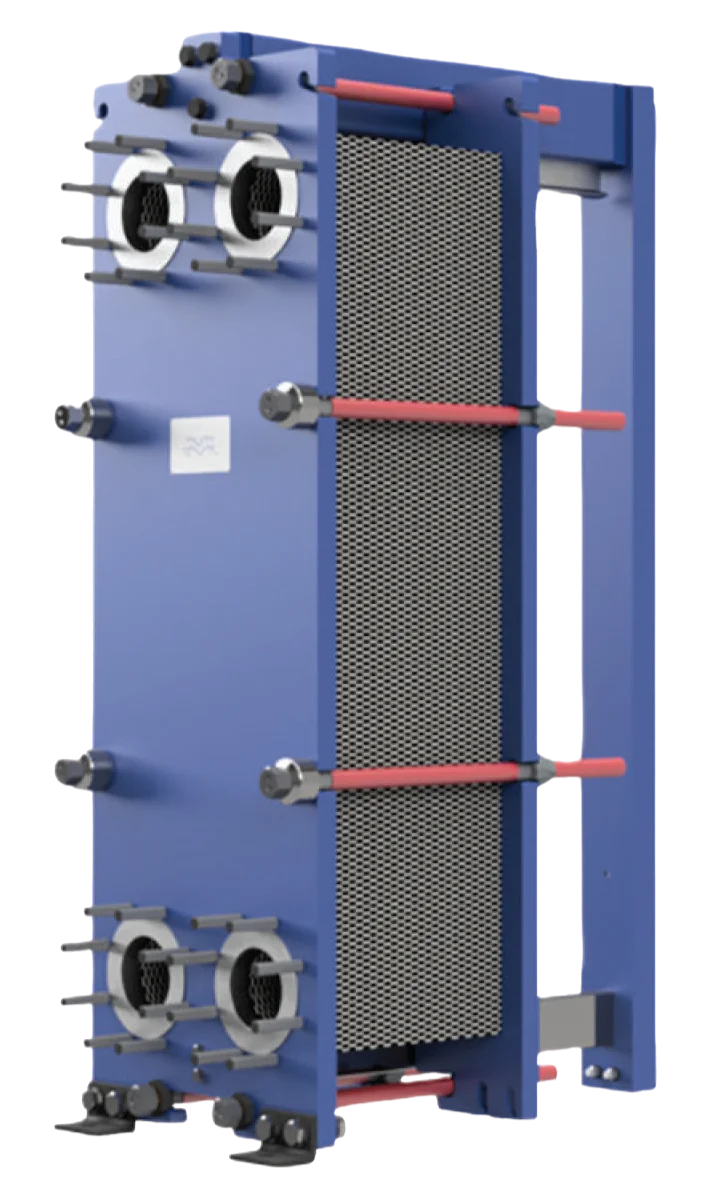

Semi Welded Plate Heat Exchangers

With our wide inventory and expert support, we ensure our customers find the perfect heat exchanger solution for their specific requirements.

Applications

Ammonia Condensers

Semi-welded plate heat exchangers are the perfect solution for ammonia condensers in industrial refrigeration systems. Their highly efficient heat transfer capabilities ensure optimal cooling, while their robust and leak-proof design enhances safety and reliability in ammonia-based applications. These energy-efficient heat exchangers help reduce operational costs and improve system performance in food processing, cold storage, and chemical industries.

Ammonia Evaporators

Designed to withstand high pressures and extreme temperature variations, semi-welded plate heat exchangers function as high-efficiency ammonia evaporators in refrigeration and cooling systems. Their compact and durable design enables consistent performance, ensuring energy savings, lower maintenance costs, and enhanced refrigeration efficiency in industrial cooling applications.

Water-Glycol Cooled Condensers

For HVAC, industrial cooling, and process refrigeration, semi-welded plate heat exchangers effectively manage heat exchange between water-glycol mixtures and refrigerants. These high-performance condensers provide precise temperature control, prevent scaling and corrosion, and ensure reliable operation in chillers, cooling towers, and heat recovery systems.

Applications

Chemical Processing

Semi-welded plate heat exchangers are widely used in chemical processing industries for handling aggressive, high-temperature, and hazardous fluids. Their durable construction and corrosion-resistant materials ensure safe, reliable, and efficient heat exchange in processes involving acids, solvents, and other reactive chemicals. These heat exchangers enhance energy efficiency, minimize downtime, and improve process reliability, making them an essential component in chemical plants, refineries, and petrochemical industries.

Marine Applications

Semi-welded plate heat exchangers play a crucial role in marine cooling systems, ensuring efficient heat dissipation for ship engines, auxiliary power units, and HVAC systems. Their compact and lightweight design makes them ideal for space-constrained environments onboard ships. Built to withstand harsh marine conditions, these heat exchangers provide superior performance, durability, and energy efficiency, reducing fuel consumption and maintenance costs in commercial ships, naval vessels, and offshore platforms.

Additional benefits of Semi Welded Plate Heat Exchangers

- Easy inspection and cleaning of the liquid side for hassle-free maintenance.

- Delivers reliable performance, making it ideal for heavy-duty applications.

- Functions as a combined condenser/desuperheater or condenser/oil cooler in a single unit.

- Floating condensation feature enhances efficiency in flooded evaporation systems.

- Fully compatible with air-liquid coolers, ensuring seamless integration in indirect cooling setups.